One customer saved over 90% of their costs when they converted their aircraft exhaust part from a billet to an investment cast.

One customer saved over 90% of their costs when they converted their aircraft exhaust part from a billet to an investment cast.

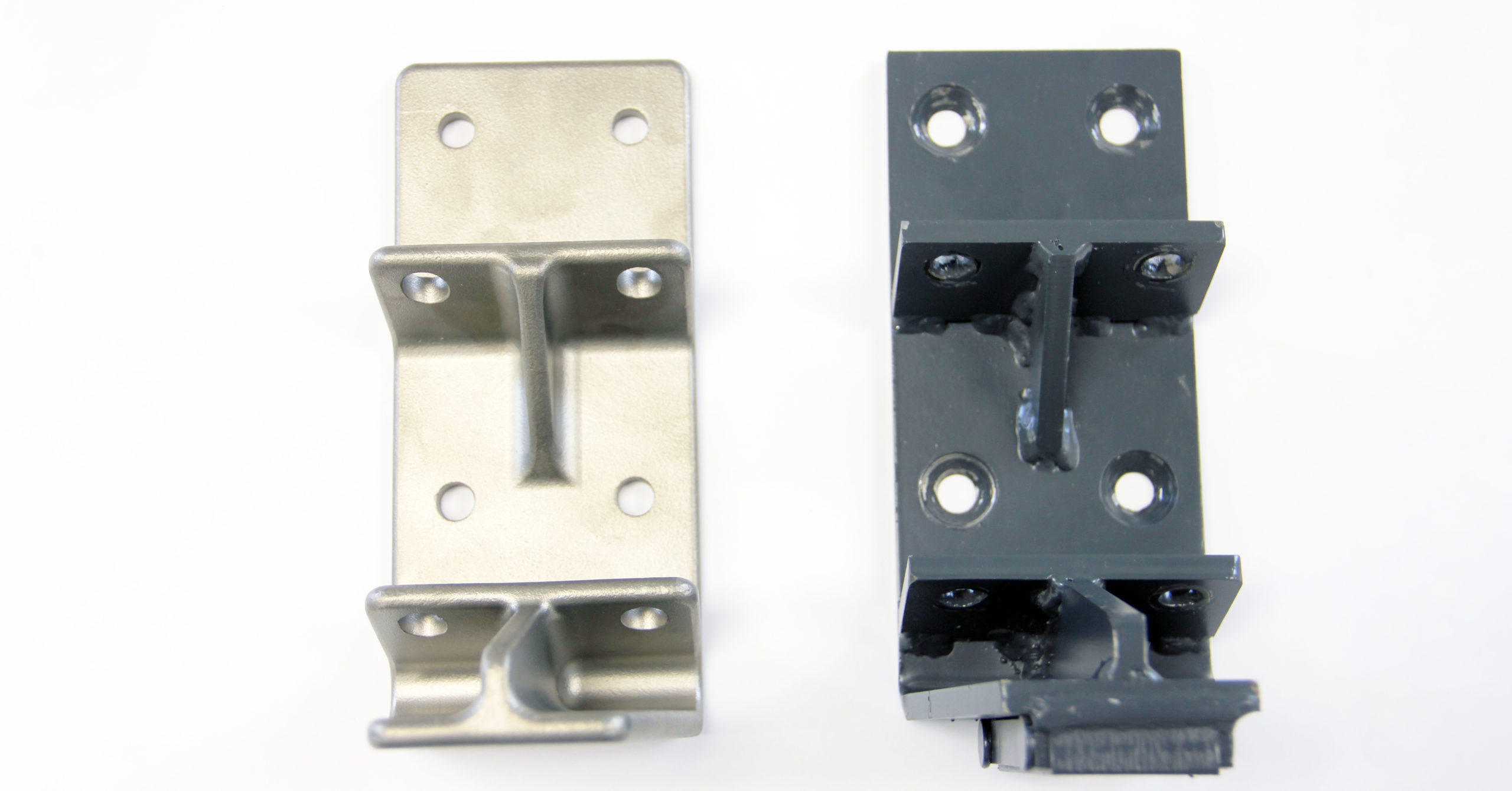

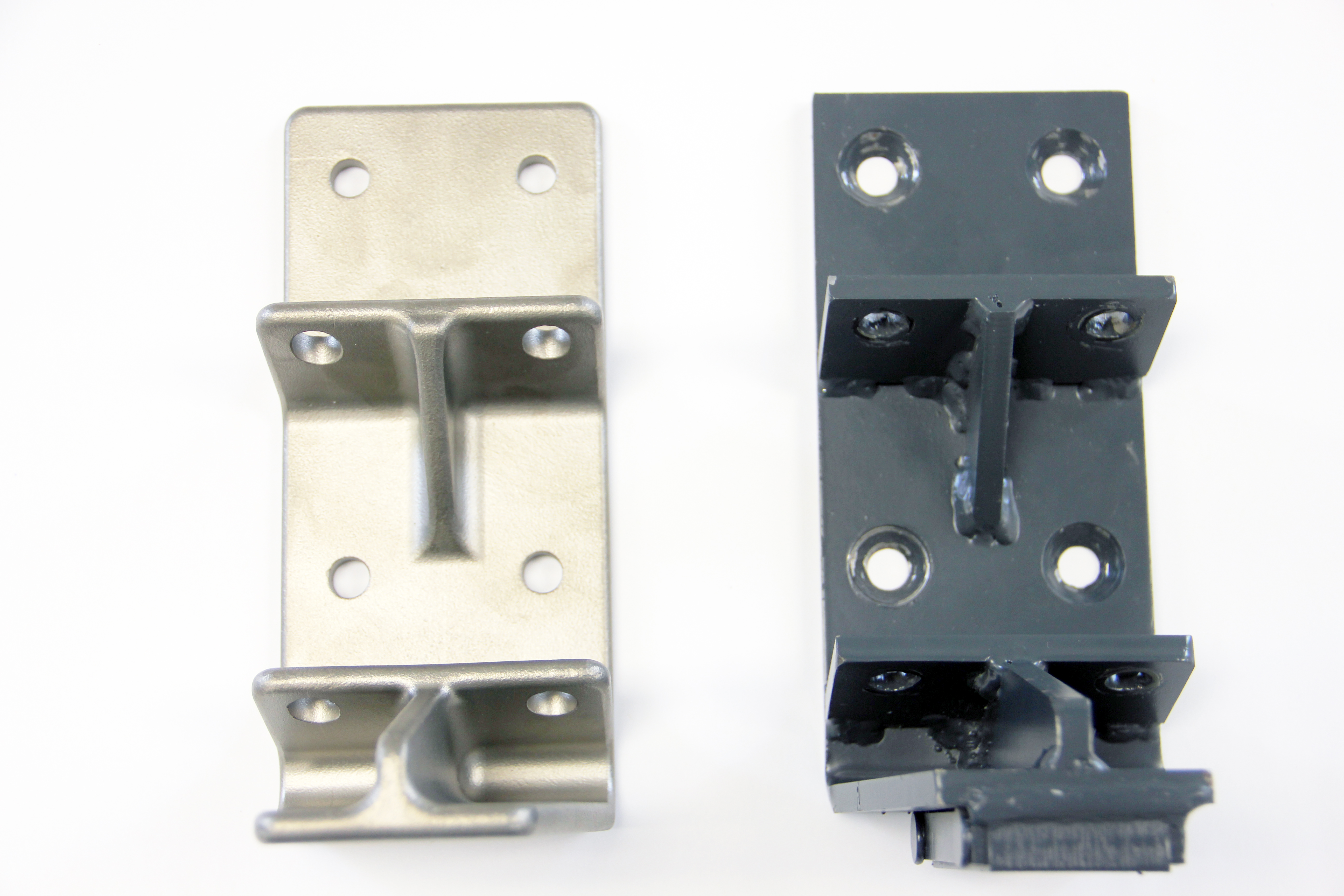

Franklin Bronze worked with one customer to convert its welded Trough Mounting Bracket to a stainless steel investment cast part. Reducing weight, simplifying logistics, improving quality, and cutting costs

The investment casting process competes with the majority of metal forming processes and offers some unique advantages. Read about advantages of investment casting over other metal forming processes – like machining, welding, sand casting, die casting and forging.

Franklin Bronze, a U.S. foundry with investment casting operations, has moved its neck ring casting customers from sand castings into investment castings. Each of these customers has reported significant savings and advantages with the new precision designs.