Franklin Bronze acquires Laser SLA 3D Printer for rapid prototyping and short runs of investment castings.

Franklin Bronze acquires Laser SLA 3D Printer for rapid prototyping and short runs of investment castings.

A look back at 2020 and our accomplishments for the year. Many changes have been made from the way we work and the way we connect. 2020 also marks the largest investment year at Franklin Bronze. Investments were made to improve, expand and modernize.

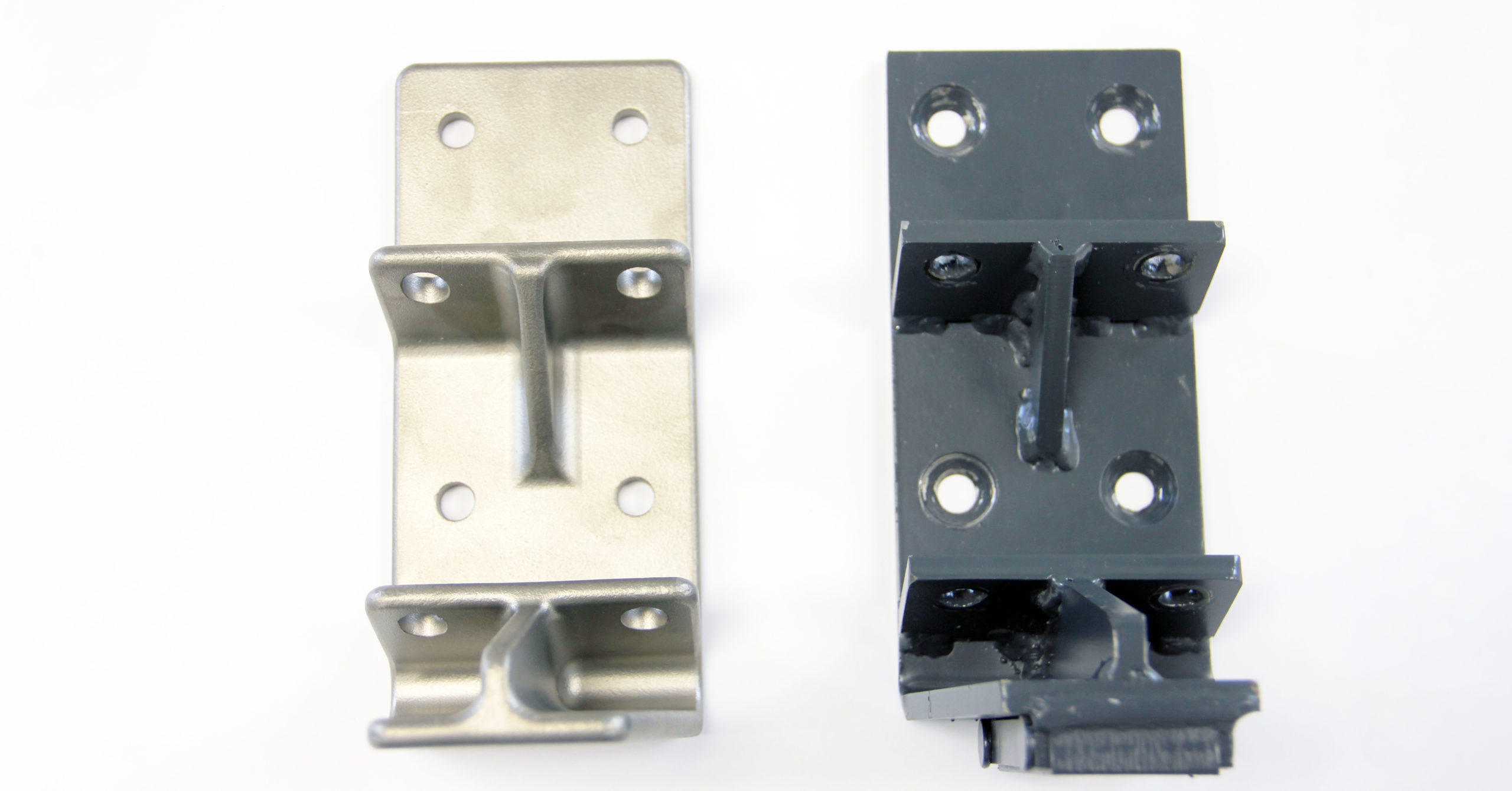

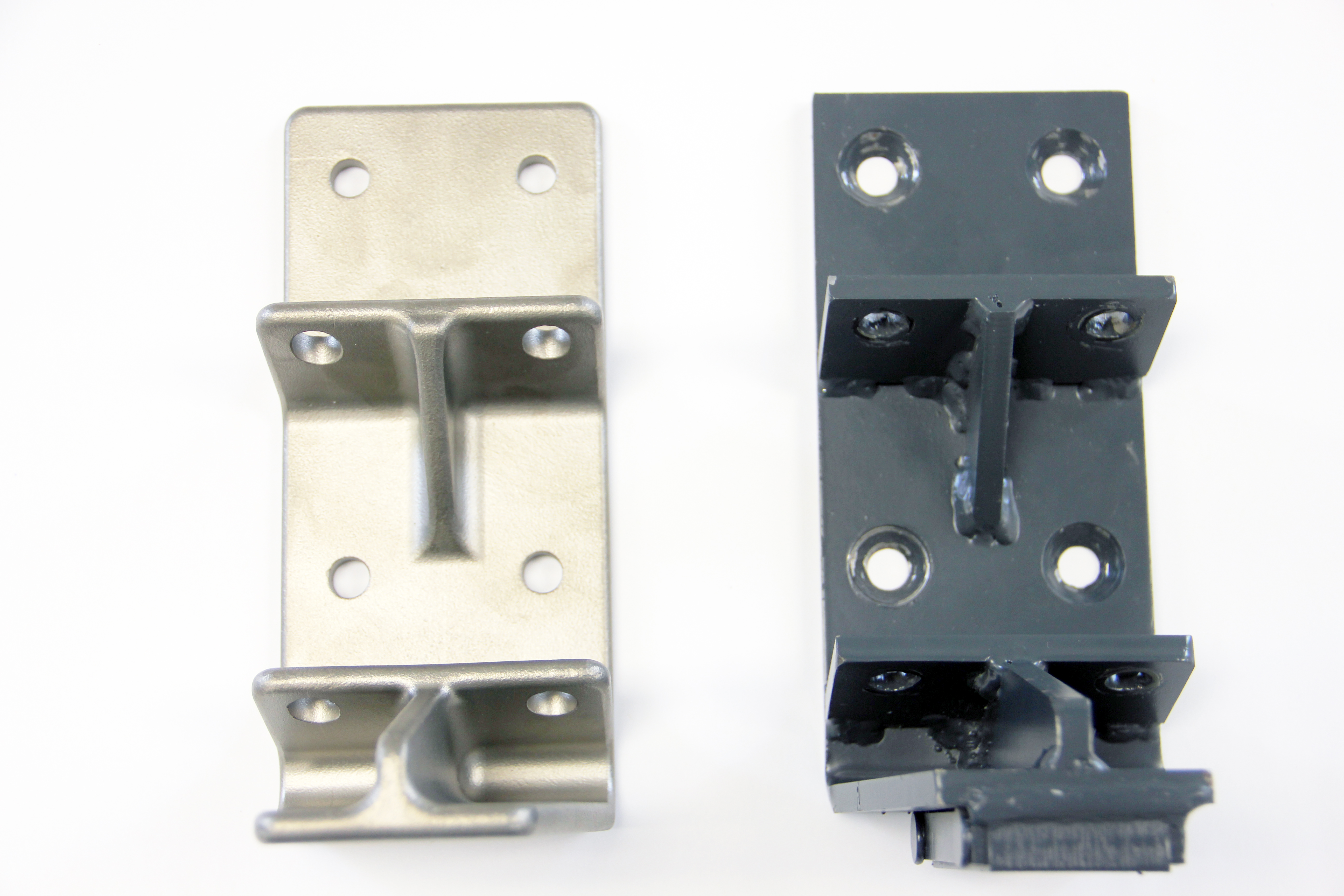

Franklin Bronze worked with one customer to convert its welded Trough Mounting Bracket to a stainless steel investment cast part. Reducing weight, simplifying logistics, improving quality, and cutting costs

Franklin Bronze Precision Components has partnered with Waste Management and in 2020 has recycled 13 tons of material from just cardboard alone!

Operations Manager, Chris Barber represented Franklin Bronze as one of four manufacturers in northwestern Pennsylvania to participate in a roundtable discussion focusing on economic development in the region. The discussion was held in conjunction with the presentation of a $1.2M grant announced by U.S. Secretary of Labor Eugene Scalia and awarded to the Education & Training Hub at the University of Pittsburgh at Titusville.

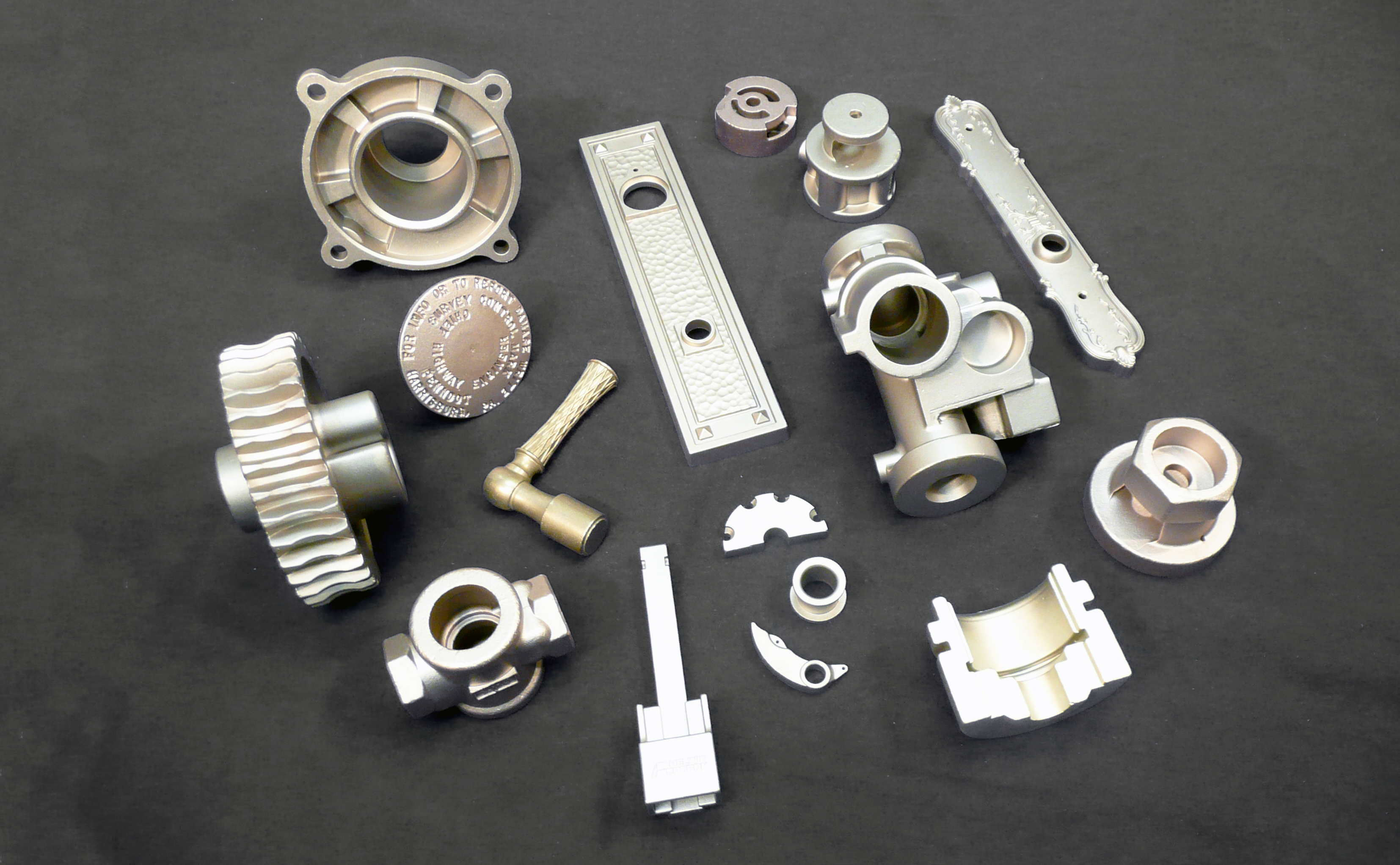

Investment Castings are used in nearly every industry and every aspect of our lives from food processing to oil & gas, water treatment, automotive, aerospace, construction, steel, transportation and more.

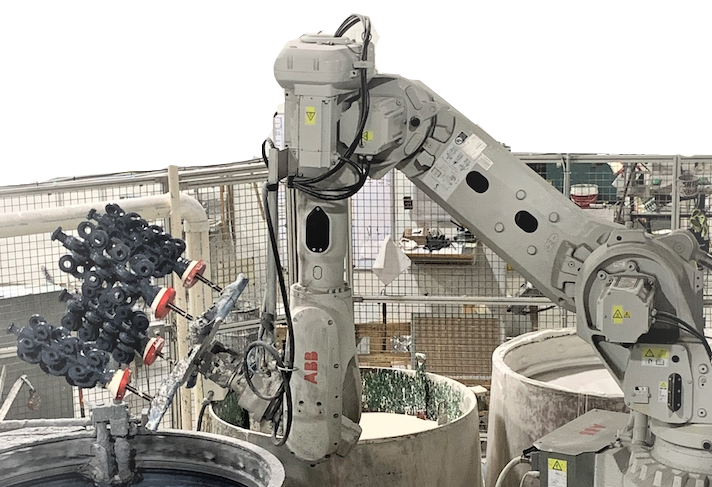

Franklin Bronze Precision Components has been on the forefront of automation when it introduced robots to their investment casting manufacturing processes in early 2005. Fast forward to 2020, Franklin Bronze continues to stay ahead with its latest introduction of new robotic technologies. Read about its latest upgrade.

The investment casting process competes with the majority of metal forming processes and offers some unique advantages. Read about advantages of investment casting over other metal forming processes – like machining, welding, sand casting, die casting and forging.

Read about the 10 advantages of investment casting. The investment casting process offers many benefits including cost savings, design freedom, close tolerances, better finishes, savings in machining time, reproducible, assembly savings, and overall – they just look better!

The COVID-19 pandemic has raised awareness on copper’s virus killing properties and that commonly touched surfaces can spread viruses and disease. According to the EPA, the surfaces of copper and its’ alloys, such as brass and bronze, are antimicrobial. Using antimicrobial copper on touch surfaces such as door handles, knobs, and other fixtures are proven to reduce the spread of viruses.

In the latest issue of Metal Center News, Shelly Winters, Marketing/Sales coordinator spoke with Editor-in-Chief, Dan Markham, on this and Franklin Bronze’s ability to cast antimicrobial bronze door handles, knobs, brackets and fixtures.